Malaysia’s construction industry faces serious labour issues and material price fluctuations affecting costs and quality control concerns.

Recognising these challenges, MGB was among the first in the industry to introduce an IBS factory to fabricate steel and aluminium formwork products 15 years ago. This was soon followed by a precast concrete facility established in 2018, further augmenting our IBS capabilities and setting the benchmark for IBS in Malaysia with high IBS scores achieved.

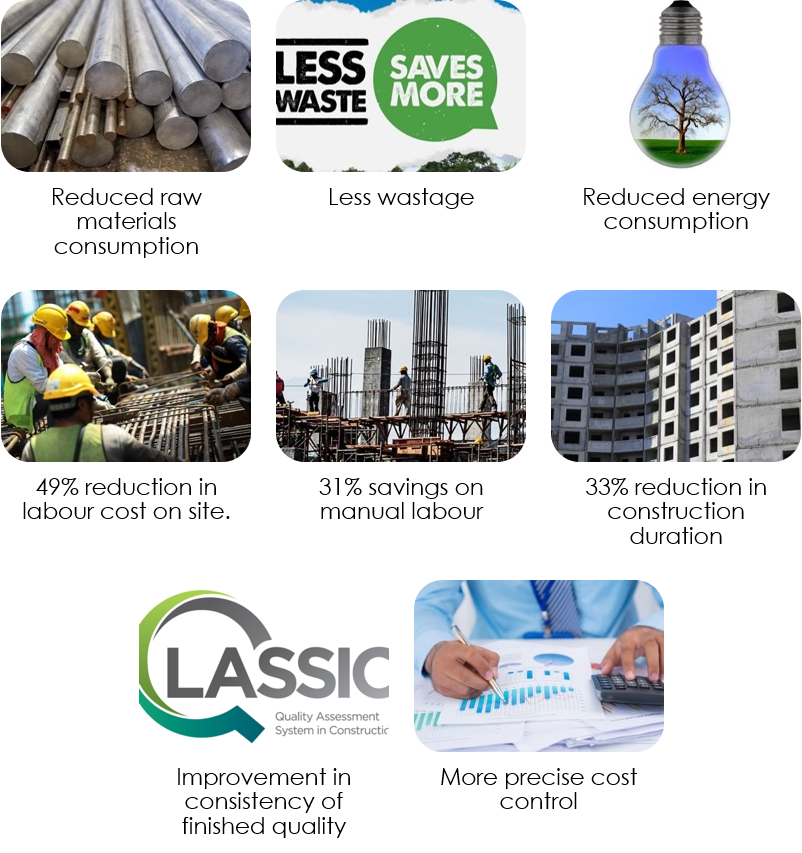

Our IBS capabilities helped reduce construction time at worksites, bringing down overhead costs and enhancing the quality of our delivery using parts pre-fabricated in a controlled factory environment.

Cumulatively, the two IBS manufacturing plants power MGB’s ability to build more than 6,000 units of properties per annum comprising affordable homes, high-rise condos and apartments as well as landed properties, factories and other infrastructure.

It has helped our clients achieve faster project completion, improve the built quality and deliver a more efficient and environmentally-friendly construction approach.

As at October 31, 2021, MGB has delivered over 4,000 units using IBS precast concrete.

SERIOUS LABOUR ISSUES

MATERIAL PRICE FLUCTUATIONS

QUALITY CONTROL CONCERNS

ROI to client:

Staircase

Half Slab & Beams

Wall